|

Supercheap 42

litre compressor fridge/freezer

LianFa

LF8042

brackground

Some testing and

experimenting has been done to see if there was any way of improving the

efficiency of the fridge without making any major modifications. The restriction

of no major modification to the fridge prevented some avenues from being

investigated further.

test

ennironment

The testing was done with

the fridge set to 0 degrees, approx 80% full of drinks and inside a habitable

room. The room temperature was not controlled and impacted on absolute results

however adjacent testing ( ie tests either side of each other ) would not have

had any significant changes in environment so should be indicative for

comparison purposes. The duty cycle was measured by utilising a data logger

sensing the load current with a sample period of 10 seconds. Results were

monitored until 3 successive results were stabilised and then recorded.

observations/ modifications

1. The DC plug and cable were changed to utilise a standard ‘ARRID’ style plug.

This is very similar to the supplied plug/ socket combination however it

required that the DC socket on the fridge be replaced as the diameter of the

socket was fractionally smaller than the more common ARRID plug and it wouldn’t

fit.

2. Testing was then done to see if the ‘off’ time of the fridge could be

increased.

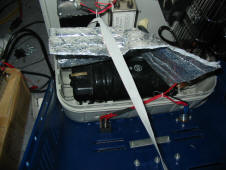

The compressor unit was

identified as a significant heat source near the fridge compartment. Various

forms of insulation were tried to see if they impacted on the ‘off’ time for the

fridge. No significant improvements were found however the insulation does

effect the cooling ( or ‘on’ time ). See the test data. The material used is

similar to ‘bubble wrap’ packaging material with a foil skin on the outsides. It

was chosen as being readily available and flexible enough to be manipulated into

place.

3. What may be worth investigating is if the insulation is acting as insulation

or as an air baffle.

4. Experimentation with the fan placement and number of fans produced some

significant improvements in the duty cycle of the compressor. The original fan

is located in the approximate centre of the motor compartment, blowing air

horizontally from the middle of the compartment through the condenser.

The problem with this location is that the hot air from the compressor, directly

below the fan, is blown through the condenser. By relocating the fan so that

cooler outside air is first blown over the condenser the efficiency of the

fridge is dramatically improved. As an indication the standard fridge, as

tested, had a duty cycle of ~59%, ( Test 1 ). With insulation and the relocated

fan the duty cycle is ~39% ( Test 6 ). The on time has been reduced by nearly

50%.

5. The fan location was not particularly critical however the proximity of the

fan intake to the outside casing was critical. Initial testing was done by

relocating the original fan to within 10-15mm of the outside of the compressor

compartment, then a flexible air baffle was added to seal the fan intake to the

outside of the compartment. The compressor run times improved from ~233 Seconds

( Test 4 ) to ~203 Seconds ( Test 5 ).

Results with a fan on the side or on the top of the compartment made minimal

difference to the duty cycle.

6. The final fan location was on the side of the compartment and fixed to the

outside of the case ie no air gap between the fan intake and the outside.

7. The modifications were undertaken to have minimal impact on the fridge to

allow for easy removal and restoration of the original configuration. As a

result the air intake for the fan Is not optimal. A significant amount of fan

noise is produced because of the restrictions to the inlet causing the air to be

sucked in the existing ventilation slits. And some mechanical vibrating noise as

a result of the fan being mounted onto the case.

8. Some experimentation was done with a 50degC thermal switch (mounted onto the

compressor) to switch the fans on/off. This appeared to have a slight

detrimental effect on the duty cycle.

9. Further investigation into switching the fan on/off with the compressor would

be warranted if only to reduce the noise and current consumption.

test results

Test 1

|

Standard |

| |

run 1 |

run 2 |

run 3 |

|

On time (sec) |

323 |

320 |

320 |

330 |

|

Off time (sec) |

223 |

220 |

230 |

220 |

|

Duty Cycle |

59% |

|

|

|

Test

2

|

With insulation only, no fans at all

|

| |

run 1 |

run 2 |

run 3 |

|

On time (sec) |

323 |

310 |

340 |

320 |

|

Off time (sec) |

187 |

190 |

180 |

190 |

|

Duty Cycle |

63% |

|

|

|

Test 3

|

With standard fan, insulation |

| |

run

1 |

run

2 |

run

3 |

|

On time (sec) |

343 |

340 |

360 |

330 |

|

Off time (sec) |

223 |

220 |

220 |

230 |

|

Duty Cycle |

61% |

|

|

|

Test 4

|

Insulation,

internal fan (near side of case,

sucking in cool air) |

| |

run 1 |

run 2 |

run 3 |

|

On time (sec) |

233 |

220 |

240 |

240 |

|

Off time (sec) |

250 |

250 |

250 |

250 |

|

Duty Cycle |

48% |

|

|

|

Test 5

|

Insulation,

internal fan (near side of case,

sucking in cool air) plus fan baffle |

| |

run 1 |

run 2 |

run 3 |

|

On time (sec) |

203 |

210 |

200 |

200 |

|

Off time (sec) |

250 |

250 |

250 |

250 |

|

Duty Cycle |

45% |

|

|

|

Test 6

|

Insulation,

small fan (80mm) bolted inside

of case, blowing across radiator |

| |

run 1 |

run 2 |

run 3 |

|

On time (sec) |

170 |

170 |

170 |

170 |

|

Off time (sec) |

270 |

270 |

270 |

270 |

|

Duty Cycle |

39% |

|

|

|

pictures

|

|

|

|

Original fan location |

Insulation-1 |

|

|

|

|

Insulation-2 |

Insulation-3 |

|

|

|

|

Insulation-4 |

New fan mounted on

inside of outer casing, condenser side of motor compartment near top. |

Thanks to Rod Egan

|