|

servicing wheel

bearings

Servicing your own wheel bearings as part of your

trip preparation or part of a regular maintenance schedule is one

job you should feel confident in doing if you own a camper trailer.

This way you know the job has been done properly as well as checking

the state the bearings & other mechanical parts such as brake

shoes, brake magnet & springs.

How to breaking down your

trailers hub is knowledge that could be very handy on the side of

the track, not only for you, but perhaps in helping someone else

that is in trouble miles from anywhere. It is always a good idea to

carry a two spare wheel bearing sets along with rear seals on trips.

what

to look for

Bearings comprise of two parts, the cup which is

pressed into the hub and the cone which is the part that contains

the rollers of the bearing. The bearing on the inside of the hub

flange, the side closest to the centre of the trailer is called the

inner bearing, while the bearing on the outside is called the outer

bearing.

When inspecting the

cone look for signs of wear, pits, chips or discolouration to the

rollers which is usually a purple or blue colour. The cup should

also be inspected for wear, damage or scoring marks. If any damage

is found they should be replaced.

Bearings should always be replaced in a

set with cup and cone together.

We

should not forget

the bearing seal which is located at the rear of the hub and

stops water and dust entering the bearings. The seal is an important

part of the bearing assembly and one which should not be overlooked

when inspecting your bearings. Look for any damage like an oversize

inside diameter or cuts and abrasions.

Wheel bearings come in

different sizes depending on their use and are matched to the load

rating of the trailer. Three things that affect the strength of an

axle include the diameter of the steel, the design load of the

bearings and the design load of the

stub machining.

When travelling into the

remoter regions of our great outdoors it is always a good idea to

carry a full set of bearings and seals in your spares kit. It is

also worth knowing they are going to fit by trying the cones in

place, but not necessarily pressing the cups in. A better idea is to

replace your present bearings, hub, cone & seal with a new set,

keeping the original as spares. You then know they will definitely fit in an

emergency on the roadside. Nothing worse than getting out your spare

bearing set and find they donít fit.

getting them

apart

The cone can be removed and

the new one re-seated in an emergency situation with a screwdriver,

however a copper dolly is the best tool for the job. This will not

damage the machined surface of the cone in case you slip. If you

have a machinist mate you could get him to turn down a short length

of pipe the same diameter as the cone to drive it home.

All bearings and seals have

a serial number stamped on them. Some camper trailers may have

mismatched components like Holden bearings and a Falcon seal

depending on the load rating of the axle and hub assembly. Make sure

you have the right parts in your spares box.

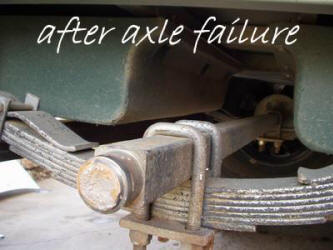

While you have everything apart it is worthwhile checking the stub

for cracks. The area in question is where a 'step' has been machined

on the stub to receive the wheel bearings. This is the most likely

place for a fracture to occur, however it is also important that you

check all machined steps on the stub.

The fracture usually starts on the bottom, so it is often not seen

until it is too late. Pay particular attention to all underneath

areas of machined 'steps'. Best way to feel if a crack is present in

a machined surface is by running your finger nail over the area or

with the aid of a small mirror.

Make sure the camper is

properly supported with suitable stands and

do not place any part of your body under the camper.

It is a good idea to

place the wheel you have taken off under the axle.

learning to do

it

|

|

|

| cleaned ready to

grease |

brake shoe, magnet

& stub inspection |

hub cleanup |

|

|

|

| brake linings

inspection |

castle nut

tightened |

dust cap reseated |

So how do you go about

performing a wheel bearing

inspection and replace the bearings and seals on your camper? There

is nothing better than hands on experience when learning a job like

this. It is not hard, anyone can do it. If you have a mate that

knows how to break down a hub, why not ask him to come around one

afternoon and then throw on a barbie after.

You can also ask your local mechanic to do the job

for you and ask if you

can watch, explaining you are going bush and would like to know how to make

emergency repairs on the side of the track.

Donít forget to ask how to remove and replace the cones in the hub.

If you are a member of a 4wd, camper trailer or caravan club you

could ask the host of the weekend get together if they could

organise a workshop on this subject.

At several of the Australian CamperTrailers Group national meets I

have conducted a practical workshop on breaking down one of my own

camper trailer hubs, showing how to inspect the bearings, remove the

cone and inspect the axle. Then putting it all back together again

including the technique of pushing grease into the bearing. You can also find suitable material on the net.

A large shifter or spanner is needed to remove the centre nut on the

stub. It is always handy to have a few extra split pins too.

Most importantly always

think safety first and never get under the trailer when it is

supported on stands alone. Park the trailer on firm level ground and

block the trailer tires on the opposite side securely so that no

forward or rearward movement is possible. Jack up the trailer

following the manufacturers instructions and secure the trailer on

jack stands of adequate capacity front and rear. Then release the

handbrake and undo the wheel nuts and remove the wheel.

When finished donít forget

to tighten your wheel nuts like I did once. The wheel came off

rolling into the bush chewing all the wheel studs in the process. I

now carry a spare set of wheel studs and nutsÖÖ. funny now.

Again there are a number of

different wheel studs & nuts used on camper trailers depending on

the axle, hub and bearing combination used. For example Landcruiser

hubs are popular for off road camper trailers. To replace a stud,

simply hammer out and a new one hammered back in on the track side,

lining up the grooves.

You may find it a little

difficult lifting the wheel back on if you have a crook back or bad

knees. A 10Rx15 tyre and steel rim combination weighs around 30 kgs.

Squatting down and lifting this weight at arms length can be

difficult. Be careful you don't bust your poofle valve. I have found it much easier

to lift a wheel into position using a 'lifting helper'. Most use a

wheel brace to do this, but anything close to hand like a stick,

tent pole, axe, shovel etc will do the job.

After placing the 'lifting

helper' on the ground under the centre of the hub roll the wheel

into position, slightly under so the top of the wheel leans out.

Rotate the hub to align the studs with the holes in the rim, then

holding one hand on top of the wheel, raise the end of the 'lifting

helper' (which will be positioned next to your leg) and push the top

of the wheel forward towards the hub. The wheel should slip straight

into position onto the wheel studs with little or no effort.

Just a note on bearing dust

caps with a grease nipple or Bearing Buddies which are designed to

prevent water entering on boat trailers. Adding too much grease can

cause the rear seal to be pushed out allowing water & dust to enter

and cause premature failure, usually at the inopportune time. It is

best to look inside the hub, inspect the bearings and regrease,

rather than to just pump grease in.

safe jacking

1 park the trailer on firm

level ground.

2 block the trailer tires on the opposite side securely so that no

forward or rearward movement is possible.

3 jack up the trailer following the manufacturers instructions.

4 secure the trailer on jack stands of adequate capacity front and

rear.

5 release the handbrake.

6 undo the wheel nuts & remove the wheel.

getting your

hands dirty

1 pry off the dust cap

using a flat bladed screwdriver.

2 straighten out the cotter pin that holds the bearing nut &

remove it.

3 remove the bearing nut and washer.

4 pull the brake drum forward along with the front bearing.

5 remove back bearing

6 remove rear seal.

Don't mix

up the bearings if you are doing more that one wheel at a time -

each bearing must mate with it's original race. The bearings wear in

& need to be matched with their respective counterparts.

bearing &

race inspection

1 thoroughly clean the

bearings and other parts in kerosene until all the old grease is

removed & set aside to dry.

2 clean the hub and spindle.

3 inspect the bearing races for heat discoloration, pitting,

scoring & any unevenness.

4 inspect the bearing for damage as above. Any out of round

rollers, cracked roller cages and rough running will indicate

replacement is required.

5 the bearing & both inner & outer races must be replaced as a

set.

axle

inspection

This gives you a good opportunity to

check the condition of the axle while you have everything apart. Pay

particular attention to the area where the 'step' has been machined

to receive the wheel bearings as this is the most likely place for a

fracture to occur. The fracture usually starts on the bottom so it

is not seen until it is too late.

Another area

worth checking is at the start of the machining itself. This area

may be

covered by the 'weld ring' if you have brakes on your trailer. You

will have to remove the backing plate to get a better look at the

suspect area, usually four or six bolts, but it will be well worth the

effect.

Best way to feel a crack in

a machined surface is by running your finger nail over the area. Not

be afraid to get your magnifying glass out to be sure. An axle

failure at highway speeds in not much fun.

re-packing

the bearings

1 place a small gob of wheel

bearing grease in one palm.

2 grasp the bearing with the other hand so that the wider end is

facing the grease.

3 force the grease into the gap between the inner race & the outer

cage so that it squeezes up through the rollers.

4 press the bearing down into the grease in a rocking motion &

continue until the grease oozes up.

5 rotate the bearing a quarter turn at a time & continue until the bearing

is completely filled with grease.

reassembly

1 put some grease into the

interior of the hub with your fingers and spread it around the

circumference of the hub.

2 place the inner packed bearing into its place in the hub.

3 place a new seal on the hub and tap it into place with a

hammer until it seats fully.

4 be sure to wipe off any grease that finds it's way onto the

outer flat surface of the seal.

5 replace the drum onto the axle spindle, insert the outer

bearing, thrust washer and axle nut.

preloading

the bearings

1 tighten the axle nut with a

spanner to make sure the seal is pressed into place.

2 back off the nut with the spanner a quarter a turn.

3 insert a new cotter pin to lock the nut in place &

bend it over the spindle.

4 re-install the dust cap, wheel and tire.

replacing bearings

The bearing must be replaced

with a complete new bearing with the inner and outer races.

1 the inner races are

pressed into place in the hub and must be driven out.

2 use a brass punch to catch the edge of the race by passing

it through the inverted hub. A few good whacks with a hammer should

drive out the old race.

3 place the new race into position and tap it in with the

hammer and punch. Take care not to mar the surface of the race.

getting the

wheel back on

You may find it a little

difficult lifting the wheel back on if you have a crook back or bad

knees. A 10Rx15 tyre and steel rim combination weighs around 30 kgs

and

squatting down and lifting this weight at arms length can be

difficult. Be careful you don't bust your poofle valve.

I have found it much easier

to lift a wheel into position using a 'lifting helper'. Most use a

wheel brace to do this, but anything close to hand like a stick, tent pole,

axe, shovel etc will do the job. Here's what you do.

1 after placing the

'lifting helper' on the ground under the center of the hub,

2 roll the wheel into position, slightly under so the top of

the wheel leans out.

3 rotate the hub to align the studs with the holes in the rim.

4 holding one hand on top of the wheel, raise the end of the

'lifting helper' (which will be positioned next to your leg) & push

the top of the wheel forward towards the hub.

5 the wheel should slip straight into position onto the wheel

studs with little or no effort.

info by Rob

July 2005

updated may 2009

|